Overview

Broaching is a machining process in which a multi-toothed tool is pushed through a workpiece at high force to form a custom profile by removing material. It is a very fast process and reliable process, and in many cases the only way to achieve certain machined features. However, since tooling must often be custom designed, the broaching process comes with great expense, retooling time and difficulty. A more comprehensive overview can be found on

Wikipedia and other sources listed in our

Final Report ( pdf)

pdf).

This project seeks to automate some computationally intense aspects of the design process, such as generating intermediate tooth profiles for complex shapes, and calculating resultant forces. In this way, we can rapidly iterate through different design options. MATLAB is used as the framework for our simulation.

User Input

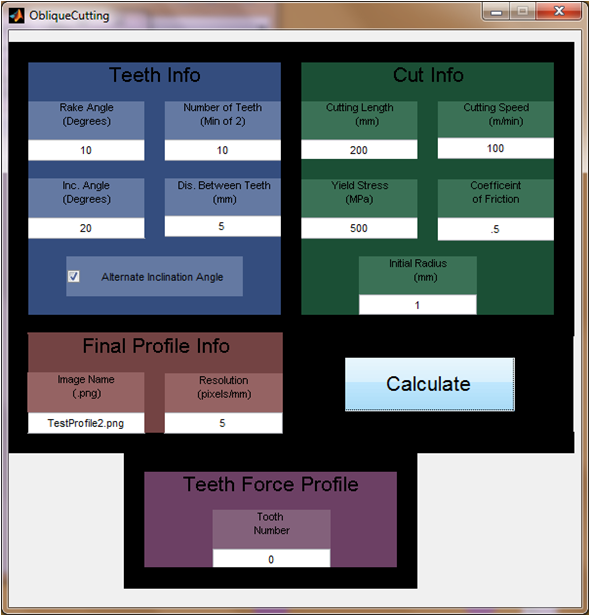

Our program has two forms of user input: the various tool parameters (number of teeth, rake angle, length of cut, etc.) and the desired broach profile.

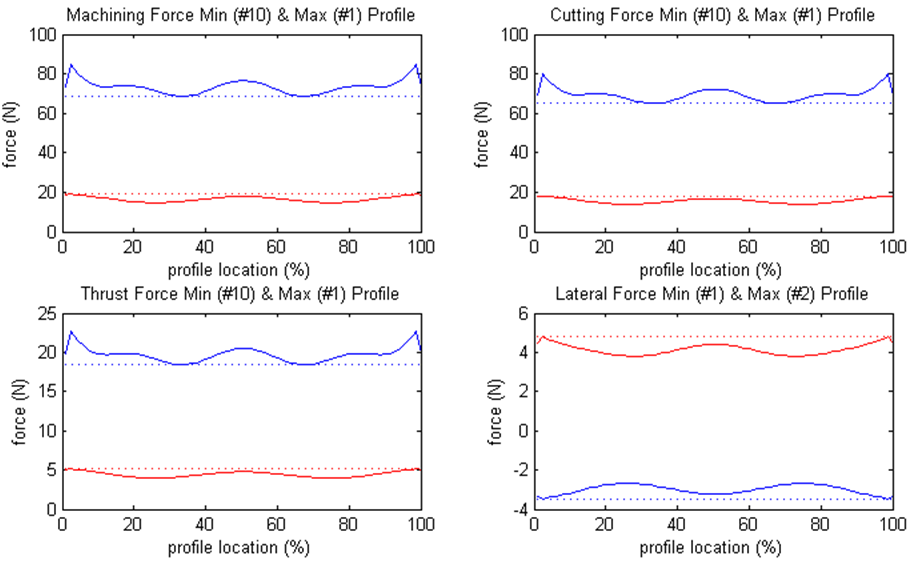

The tool parameters are input by way of a graphical user interface:

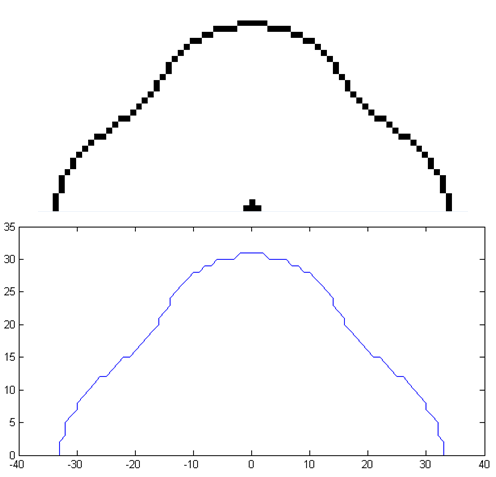

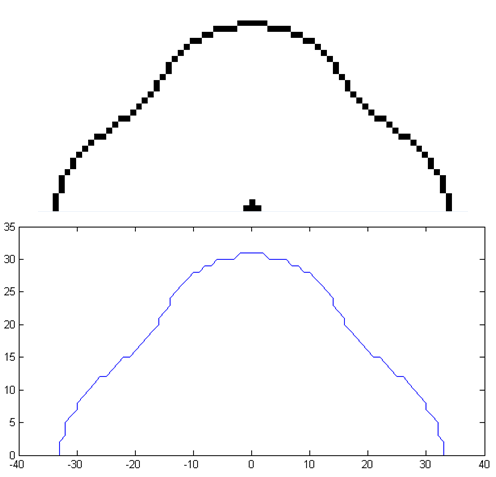

The profile is input as a PNG image and interpreted by our simulation:

Program Procedure

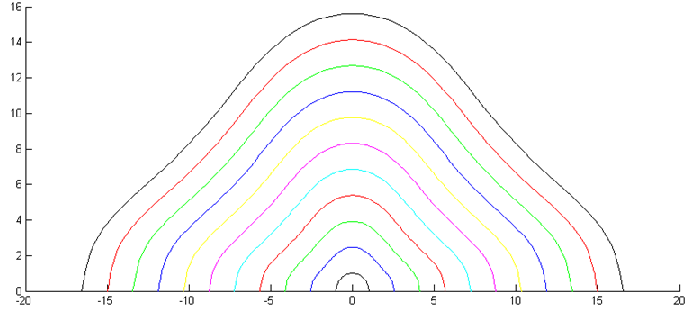

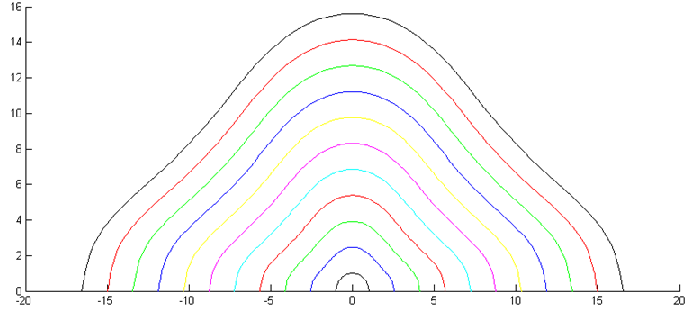

The simulation uses MATLAB's built-in polynomial fit function to create a smooth final profile, then calculates evenly spaced intermediate tooth profiles by linearly interpolating a set of coordinates between every point on the final profile and an arbitrary starting profile, for which we use a semi-circle. It is arbitrary because it has no effect on the final profile.

Force Calculation

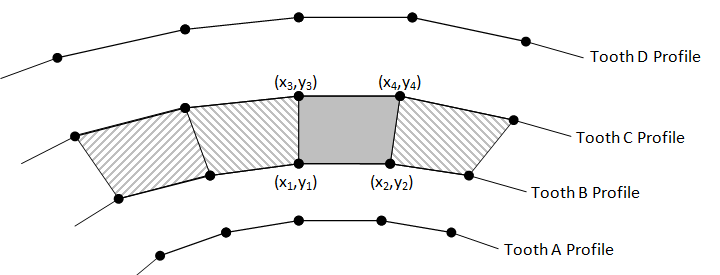

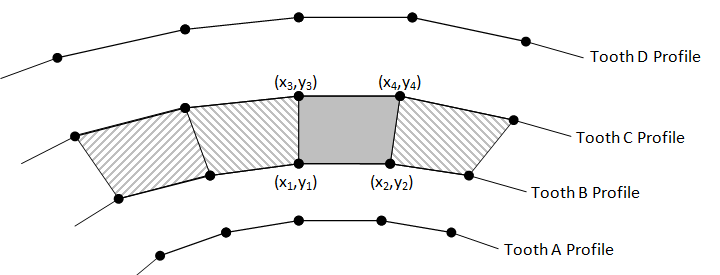

Subsequently, the forces on each tooth can be calculated using their rake angle and the cut area, calculated by numerically summing individual areas as such:

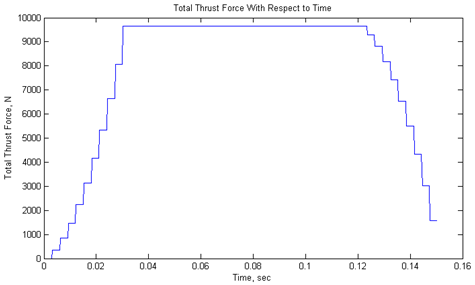

Forces can be calculated for orthogonal (simpler) and oblique (lower force, more common) cutting.

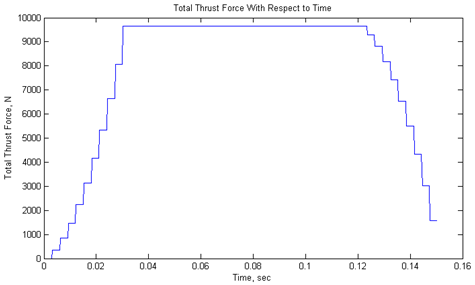

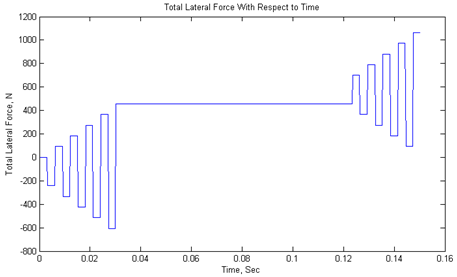

For oblique cuts, inclination angle is alternated on subsequent teeth to decrease lateral forces:

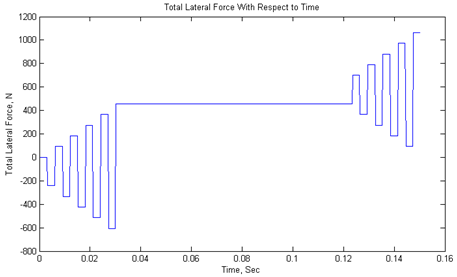

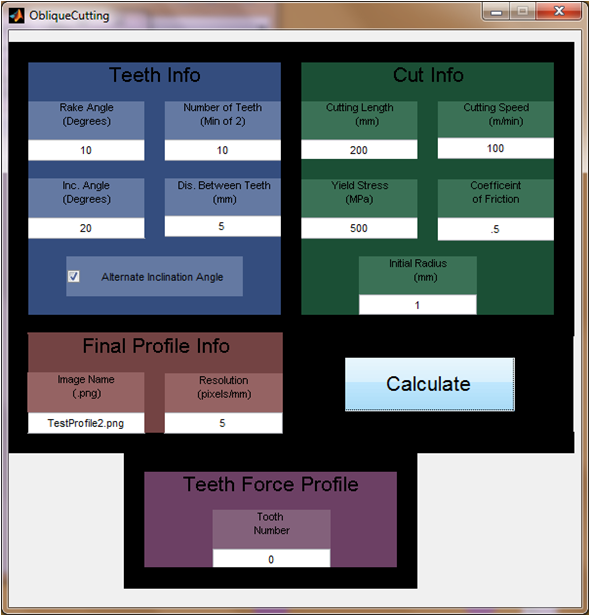

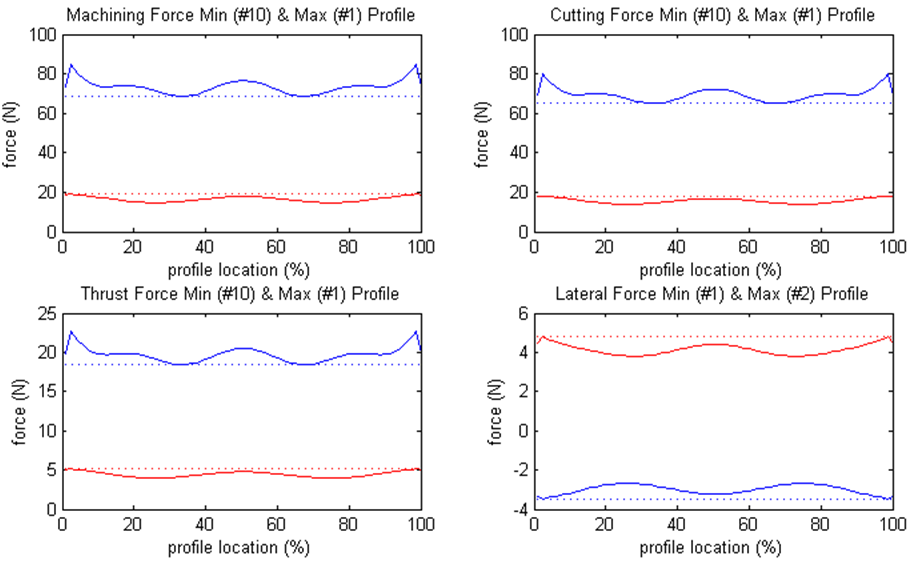

From the numerical calculation, it is also possible to see what sections of the tooth profile see the highest forces. In theory, this could be used to further optimize intermediate broaching profiles, but was outside the scope of this project:

Conclusion

The outcome of this project was a simulation which could model slot broaching in a wide range of situations. Despite some limitations, we believe it could be a useful tool for broach profile design with some additional development.

A more comprehensive discussion can be found in our

Final Report ( pdf)

pdf).