The class was tasked with designing a product that would improve the living and working conditions of aging long haul truck drivers. This class project was in partnership with International Truck & Engine Corporation, so the product can be integrated into the truck design.

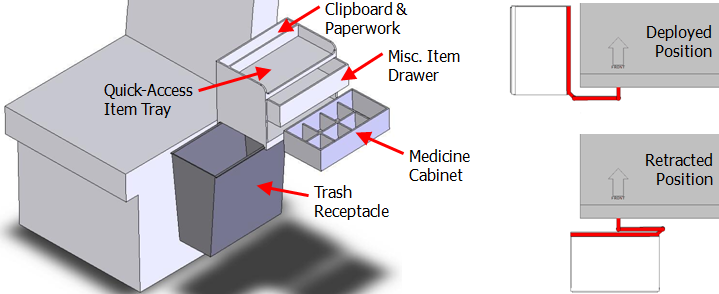

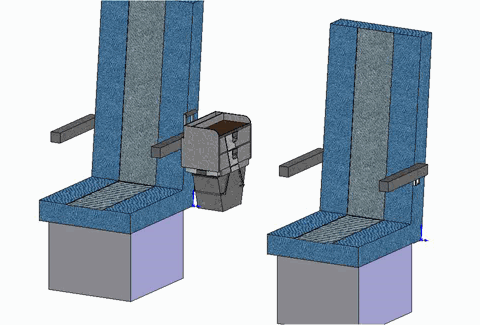

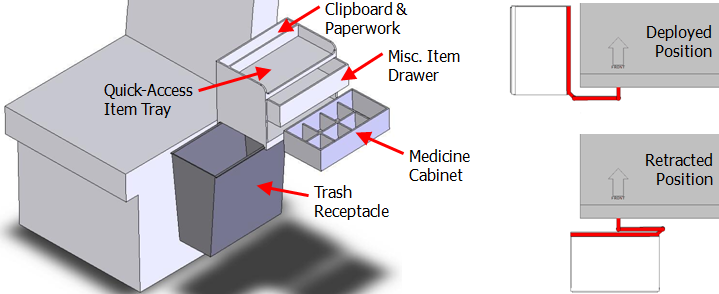

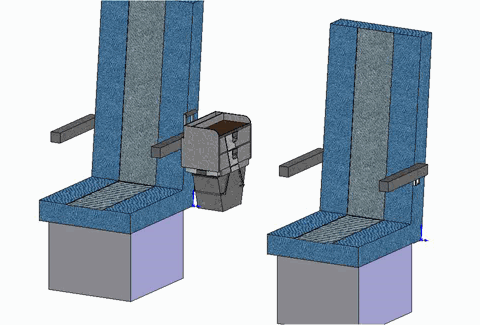

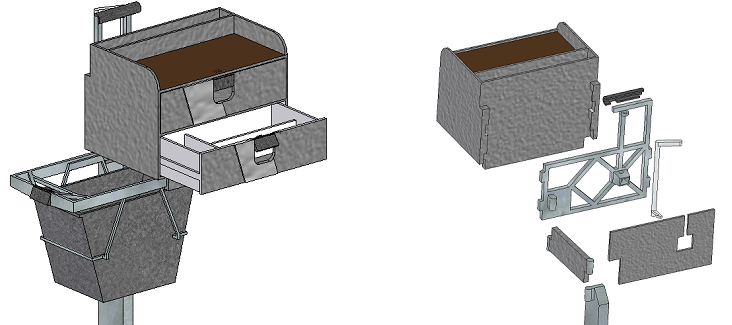

Our team developed a center console, usable from the driver's seat for paperwork, storage, garbage collection and convenient access to medicine. The console can retract to provide normal walk-through access to the rear compartment.

Phase 1: Identify and Understand the Opportunity

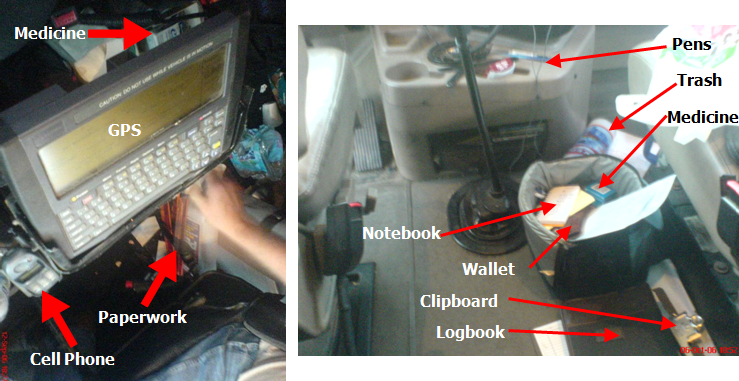

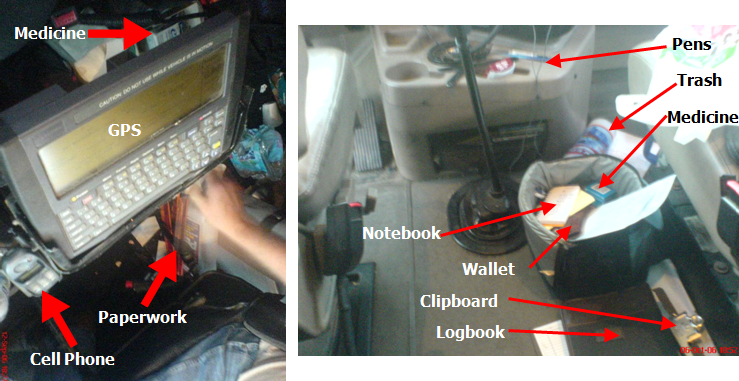

Our first step was to become familiar with the user and product, so we went to a truck stop to talk to some drivers. We interviewed two aging truck drivers to find out how they interacted with their truck cabin while working and relaxing. We took notes, snapped photos and recorded audio interviews.

The first opportunity that jumped out at us was storage. It was clear that existing solutions did not fit most of the drivers' needs, and improvised containers were everywhere. Some common themes begin to emerge: paperwork, medicine and trash.

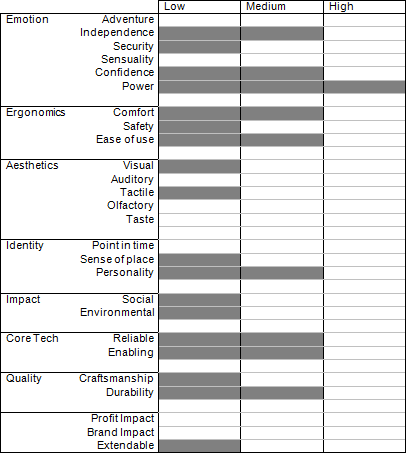

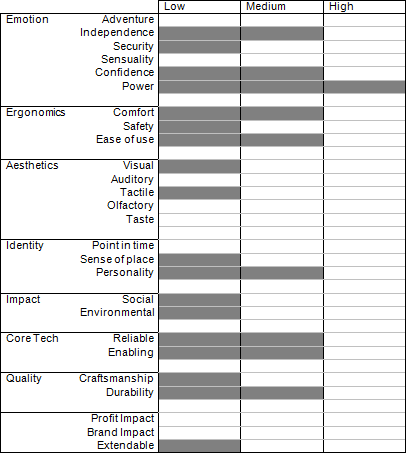

A Value Opportunity Analysis helped to quantify how users felt about their trucks, and how strongly those emotions were associated with the experience. For example, an 18-wheeled truck gives drivers a tremendous sense of power, as well as confidence in themselves and the reliability of the technology, but safety and security are clearly lacking.

This analysis was influenced by a survey we distributed to truck drivers. This tool is not intended to be perfectly scientific, but it helps to guide you to make decisions based on real user input.

We brainstormed over a hundred opportunities, thinking about existing problems or shortcomings where a new innovation could distinguish the brand and attract new customers. Eventually, we narrowed it down to:

"Optimizing space between driver & passenger seats" - this floor space is used as a pathway between the driver's seat and rear sleeper cab, but often serves double duty as storage space.

Phase 2: Create a Design to Satisfy the Opportunity

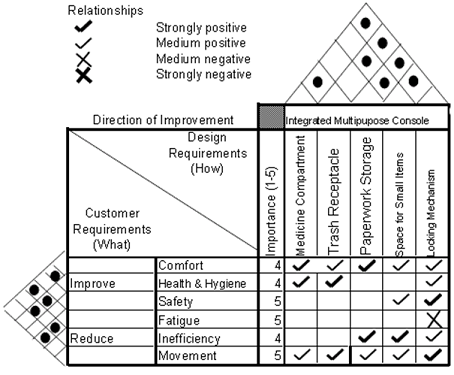

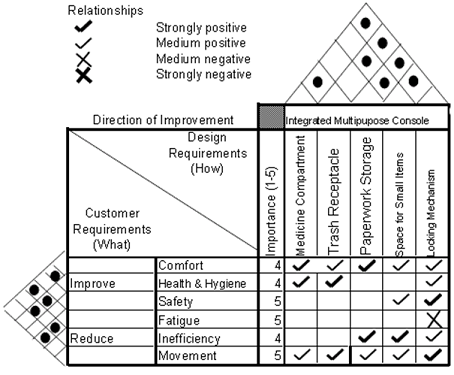

Once we figured out a problem, it was time to find the solution. We brainstormed dozens of ideas, and started whittling them down. First we needed to figure out what features our product could have, and how they intersected with the customer's needs. For this, we used another trade study tool, the House of Quality:

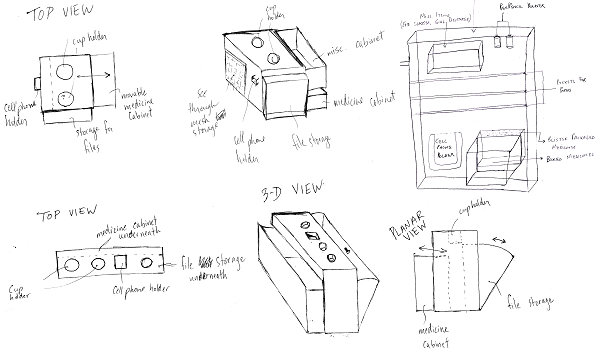

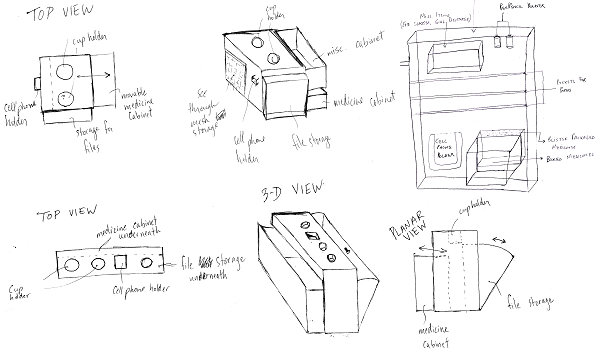

To integrate all of these features, the real design work had to begin. We looked to similar products for inspiration - both aftermarket truck products and simple office products - to understand what people were buying. We went through a lot of options:

Eventually, we settled on a hinged design which allowed our device to function like the center console in passenger cars without impeding the normal walking paths around the cabin.

The design implemented everything we learned about user needs through our research. We went back to the truck stop to solicit feedback from potential users, and the response was quite positive. One must always keep the end user in the design loop, or else you run the risk of getting off track and ending up with something no truck driver would want.

Phase 3: Refine the Solution

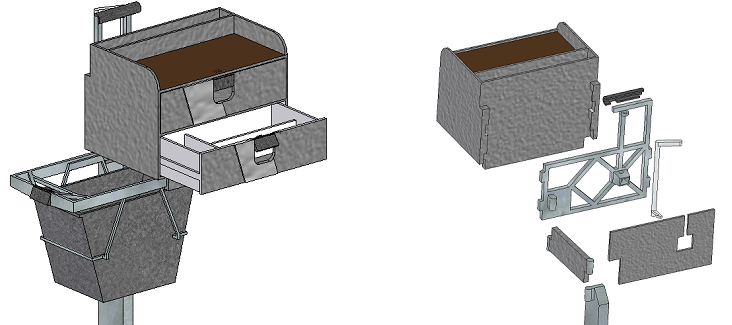

The last phase was mostly engineering: figuring out all the little details and how everything comes together. The CAD model was refined to a more manufacturable state, and the functionality remained largely unchanged.

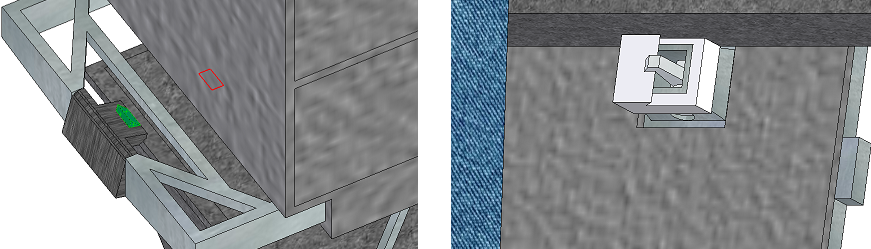

A spring-loaded latch was used to lock the console in place, connected to a rubber handle on top which could be reached from the driver's seat in both the extended or retracted position. The structure was lightweight plastic, with a metal frame in back for support.

All moving parts and compartments had to latch closed so they wouldn't open while driving. One concern was crash-worthiness: the latch had to be balanced so that the handle's inertia wouldn't actuate during a crash.

We built a prototype to test how the device might be used in real life, using full-scale mockups. The build quality was a bit rough, but it was fully functional and provided us with many insights. Our prototype was much heavier than anticipated, and stressed the importance of making the final product lightweight.

We presented the design to our class and corporate sponsors, with a positive reception overall. The design was eventually patented with the help of Navistar, and may enter use in some form in one of their future models.