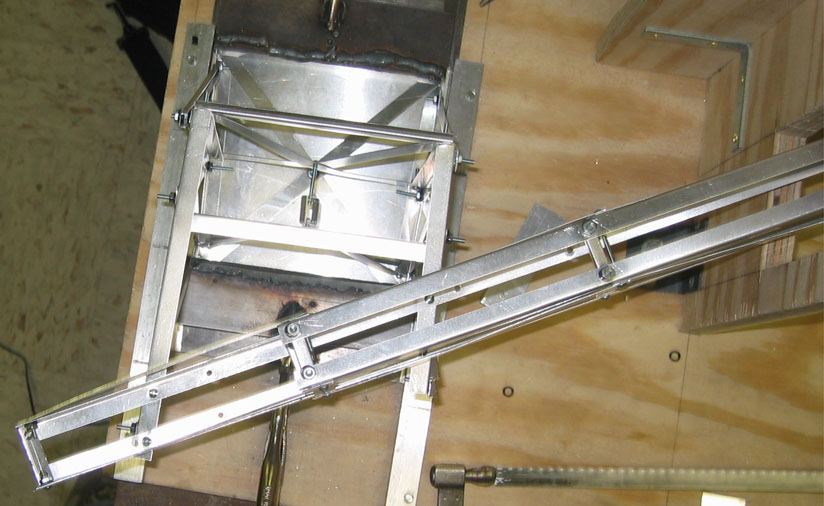

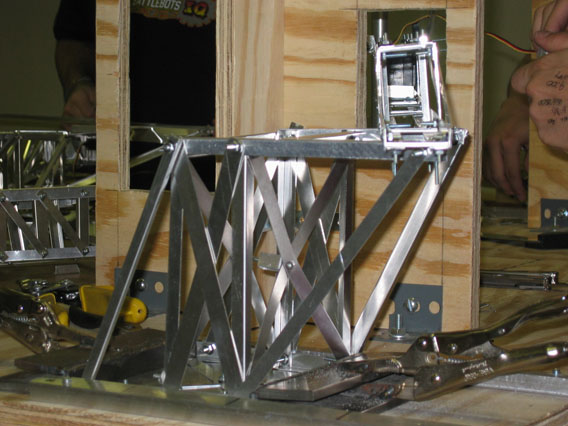

Thus, our structure incorporates the simplest and most effective design features. We chose to build a structure that goes through the smaller opening in the wall to provide the most direct route to the weight. This design requires less material and reduces the overall weight of the structure. That decision affects the dimensions of the arm, so we had to create the stiffest arm that would still fit through the opening. The arm itself is inline with the weight so it undergoes little torsion, therefore it was designed primarily to withstand bending. Using a combination of Pratt/Warren type trusses and a box-beam for rigidity, we created our ultra-stiff arm.

This arm is attached to the base through an offset platform that has alternating tension and compression members to withstand the applied torsion from the arm and the weight. The base is designed to be as rigid as possible so that the magnified deflection at the lift mechanism is very small. As a result the deflection under the load of the weight is only 1/8 on an inch. At the other end of the box-beam arm, we have our hinged-arm lift mechanism attached to the servo through a 5/2 gear reduction. This arm has a range of motion of 48 degrees and with the counterweight consistently lifts 4.125 inches.